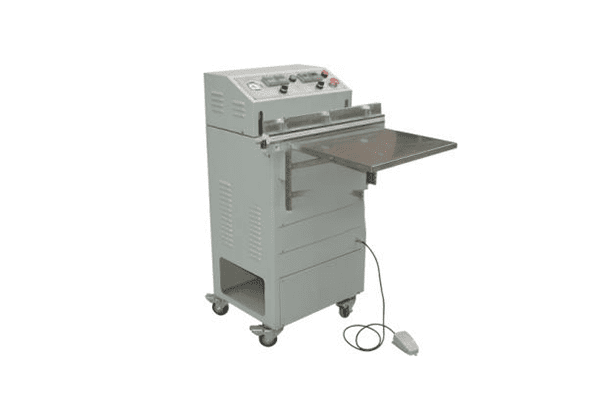

External Pumping Vacuum Packaging Machine

The external pumping vacuum packaging machine is a floor-standing model featuring a 600 mm sealing line. Its nozzle-free design evacuates air directly through the sealing bar, eliminating contamination risks in a chamber. Equipped with a silent oil vacuum pump (or optional oil-free pump), microcomputer control, and adjustable stainless-steel workbench. Lockable casters allow easy relocation.

Specifications

• Sealing Width: 600 mm

• Pump Type: Silent oil pump / oil-free pump option

• Control System: LCD touch microcomputer—vacuum, seal time, and temperature programmable

• Power Supply: 220 V/50 Hz, 1.2 kW

• Construction: Powder-coated steel or 304 SS shell; SS workbench

• Dimensions (L×W×H): 850×700×1 200 mm (with casters)

• Weight: 130 kg

• Seal Method: Heated sealing bar, 0–300 °C adjustable

• Workbench Height: 800–950 mm adjustable

• Ultimate Vacuum: ≤ 5 Pa

Key Features

• Nozzle-Free Chamber: Direct bag evacuation avoids particle buildup and simplifies cleaning.

• Silent Vacuum Pump: Noise < 60 dB(A); oil-free option eliminates oil mist.

• Microcomputer Control: PID temperature control and precise vacuum calibration with memory presets.

• Alarm System: Automatic fault alerts for open lid or operational errors.

• Anti-Pinch Safety: Sealing bar retracts instantly on obstruction to protect operators.

• Adjustable Workbench: Accommodates various bag sizes and production lines.

• Lockable Casters: Smooth mobility and stable locking position.

Technical Highlights

I. Nozzle-Free Vacuum Chamber Technology

• Multi-venturi matrix: 360° air extraction in 3.2 s (vs. 8–12 s industry average)

• Sealed hydraulic actuators: Moisture-, oil-, and acid-resistant; 75% longer maintenance intervals

• Adaptive sealing geometry: Handles irregular packages for medical, aerospace, and gourmet products

II. Silent Pump Engineering

• Titanium helical rotors with harmonic dampers: 18 dB noise reduction

• DLC-coated oil-free bearings: Maintenance-free, 20 000 h lifespan

• Phase-change cooling channels: Stable operation up to 55 °C ambient

• Regenerative braking: 43% energy savings

Applications

• Food Packaging: Preservation, flavor aging, liquid nitrogen flush

• Medical Devices: Sterile barrier sealing before/after sterilization

• Electronics: Moisture, oxidation, and corrosion protection

• Hardware Tools: Rust and impact resistance for long-term storage

• Chemicals: Sealing powders, granules, and secondary containment

Quality & Service

• Rigorous QC: Incoming inspection, in-process audits, and dynamic testing meet CE/UL/RoHS

• Ready Stock & Fast Delivery: Standard units available; supports bulk and custom orders

• OEM/ODM Customization: Seal length, bench size, UI layout tailored to your line

• Lifetime Support: Remote diagnostics, firmware updates, and spare-parts supply

Deliver contamination-free, rapid, and reliable vacuum packaging with our external pumping vacuum packaging machine—engineered for industrial-grade performance across food, pharma, electronics, and hardware sectors.