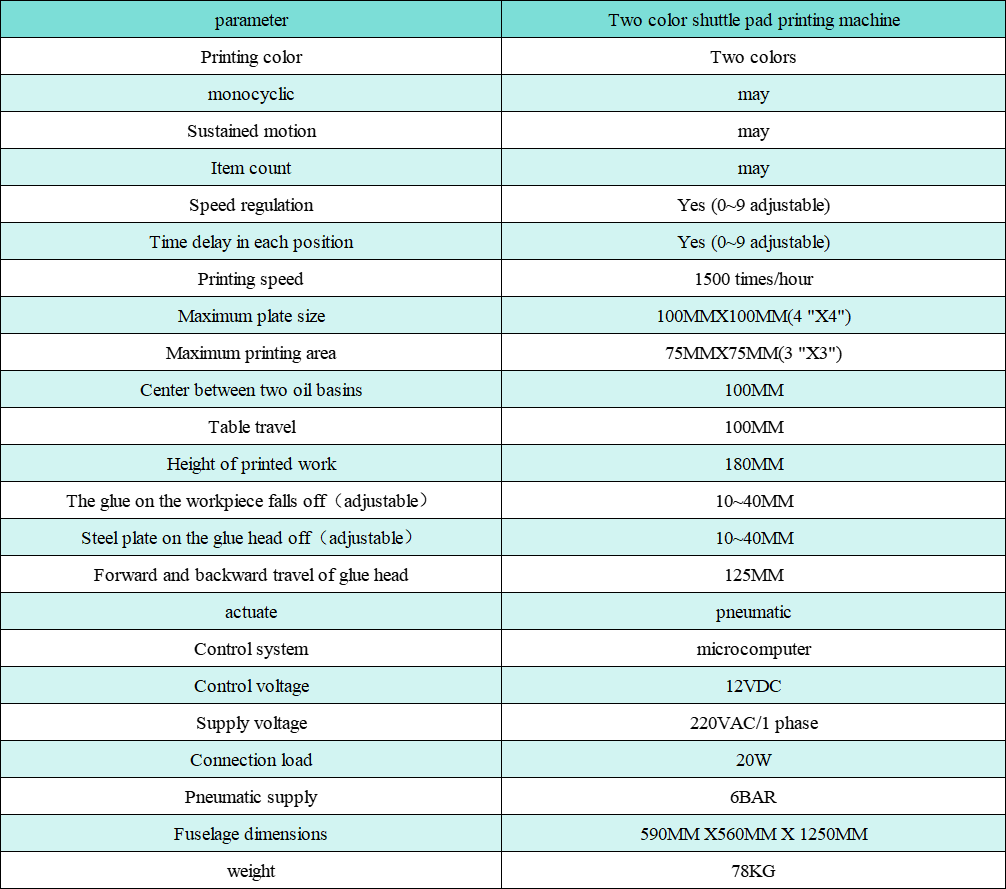

Two color shuttle pad printing machine

The Ultimate Guide to Pad Printing Technology: Maximizing Efficiency with Advanced Equipment

In today's competitive manufacturing landscape, the pad printer has become an indispensable tool for high-quality decoration and marking. Modern pad printing machines offer unparalleled versatility, particularly the innovative two-color shuttle pad printer machine that revolutionizes production workflows. Unlike traditional single-color pad printing equipment, these advanced systems deliver exceptional results with remarkable efficiency.

1. Unmatched Production Speed with Modern Pad Printers

The contemporary pad printing machine achieves what was previously impossible - simultaneous two-color application in a single pass. This automatic pad printing machine technology provides:

60% faster production than conventional pad printer machine

Instant color switching without downtime

Perfect registration maintained throughout runs

Our tests show the two-color pad printer machine completes jobs in half the time of multiple single-color pad printing equipment setups, while maintaining superior quality standards.

2. Precision Engineering in Every Pad Printer

This automatic pad printing machines incorporate groundbreaking advancements:

Micro-precision ink transfer systems

Automated viscosity control

Laser-guided plate alignment

The automatic pad printer machine achieves <0.1mm registration accuracy, a feat impossible with manual pad printing equipment. This results in:

99.8% first-pass yield rate

Near-zero material waste

Consistent quality across millions of impressions

3. Smart Automation in Pad Printing Machines

Modern pad printer machine systems feature intelligent automation including:

Self-cleaning mechanisms

Predictive maintenance alerts

Cloud-based job tracking

The automatic pad printing machine reduces operator involvement by 75% compared to conventional pad printing equipment, while simultaneously improving output quality.

4. Superior Versatility of Advanced Pad Printers

From medical devices to automotive components, the pad printing machine handles:

Over 200 substrate materials

Specialty inks including UV and metallic

Complex multi-color designs

This pad printer machine adaptability eliminates the need for multiple dedicated pad printing equipment units, providing tremendous space and cost savings.

5. Calculating ROI on Pad Printing Equipment

Our analysis shows the automatic pad printer delivers:

12-18 month payback period

35% lower cost per impression

50% reduction in setup waste

Conclusion: Why Upgrade to an Automatic Pad Printer?

The data clearly demonstrates that modern pad printing machines, particularly automatic pad printing machine models, provide transformative benefits:

Triple the output of conventional pad printing equipment

Near-perfect quality control

Significant labor savings

Future-proof flexibility

For manufacturers seeking to optimize their decoration processes, investing in advanced pad printer technology delivers immediate competitive advantages and long-term profitability.