Box Compression Tester Guide

Technology parameter

Capacity selection | 500kg |

Paper tube outer diameter | 200mm |

| Test space | 150*150 |

| Test speed | 10~150mm/min |

Force resolution | 1/200000; |

Display resolution | 1N |

| Accuracy level | 1 |

| Displacement unit | mm, cm, in |

Power unit | kgf, gf, N, kN, lbf |

| Stress unit | MPa, kPa, kgf/cm², lbf/in² |

| Control mode | microcomputer control (optional computer operating system); |

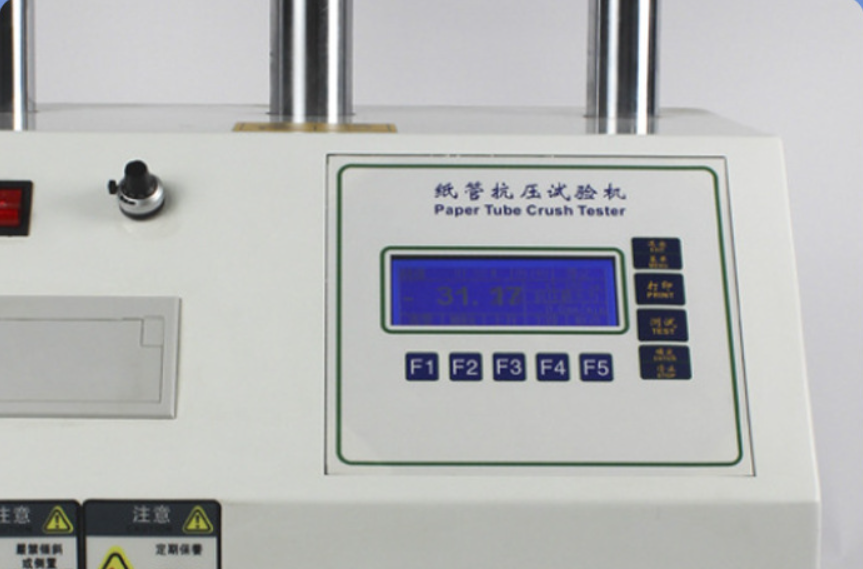

| Display mode | electronic LCD display (optional computer display); |

| Software function | Chinese and English language interchange |

Feature

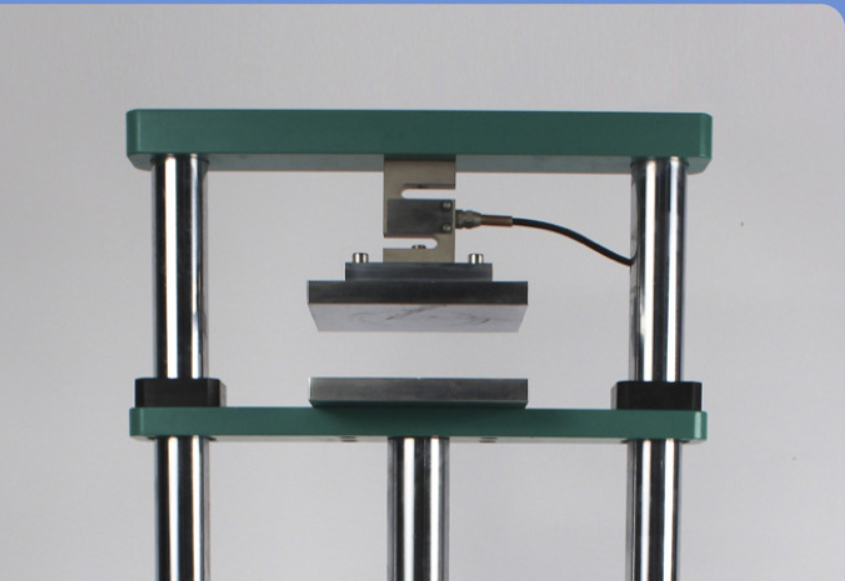

sensor

The use of high-precision sensors, high-speed processing chip design, to ensure sampling accuracy

control panel

Smart LCD digital display, visually display the control panel,Adjustable speed, all Chinese LCD display operation interface, a variety of units to choose

printer

Equipped with a micro printer, you can print test results directly

Building upon the core function of evaluating compressive strength in 200mm outer diameter paper tubes, modern compression testers embody precision engineering, advanced material science, and data intelligence capabilities far exceeding basic load measurement. This expansion details the critical characteristics defining high-performance systems for cylindrical packaging validation, emphasizing innovations in structural design, control algorithms, failure analysis, and industry-specific adaptability.

I. Advanced Mechanical & Structural Engineering

Triaxial Rigidity Architecture

Monolithic Frame Construction: High-grade cast iron or welded steel frames with box-section columns (≥100mm thickness) minimize elastic deformation under load (typically <0.05% FS at max capacity)

Precision-Ground Platen System: Hardened steel platens (HRC 60+) with parallelism tolerance ≤0.02mm/m, featuring interchangeable surface inserts:

Textured grips for anti-slip testing

Spherical self-aligning seats for uneven tube ends

Temperature-controlled platens (-30°C to +150°C)Anti-Buckling Guidance System: Linear ball-bearing guided columns with preload adjustment to eliminate lateral deflection during asymmetric failure

Dynamic Loading Subsystems

Servo-Electric Drive System: Brushless AC servo motors with planetary gear reducers (1:20 ratio) enabling:

Speed range: 0.1–500 mm/min

Positional accuracy: ±2 μm

Noise level: <55 dB(A)Hydraulic-Assisted Options: For capacities >100 kN, integrated hydrostatic bearings eliminate friction in load columns

II. Precision Measurement & Sensor Technology

Multi-Sensor Metrology Array

Primary Load Cell: Strain-gauge based sensor with temperature compensation (0.0005% FS/°C), ranges switchable from 1%–100% FS (e.g., 5kN/50kN/100kN)

Auxiliary Measurement Systems:

Laser Extensometer: Non-contact radial deformation measurement (accuracy: ±5 μm)

Acoustic Emission Sensors: Detect micro-fractures at 100–900 kHz range

Digital Image Correlation (DIC): 3D surface strain mapping via dual 5MP camerasReal-Time Compensation Algorithms

Frame deflection compensation via embedded displacement transducers

Inertial compensation for high-speed testing (≥100 mm/min)

Moisture content correction using IR sensors (ISO 287 compliant)

Application

suitable for paper tube with outer diameter of 200mm, also known as paper tube pressure testing machine