HW-1168V Vertical Machining Center

The HW-1168V features an optimized C-type structure with a golden ratio design for superior machine rigidity and stability.

It has the characteristics of high-speed and high-precision processing, mainly used for high-precision and high-efficiency

processing of small and medium-sized molds, and can be widely used in automotive, machinery, instrumentation, light textile, electronic instruments and other industries.

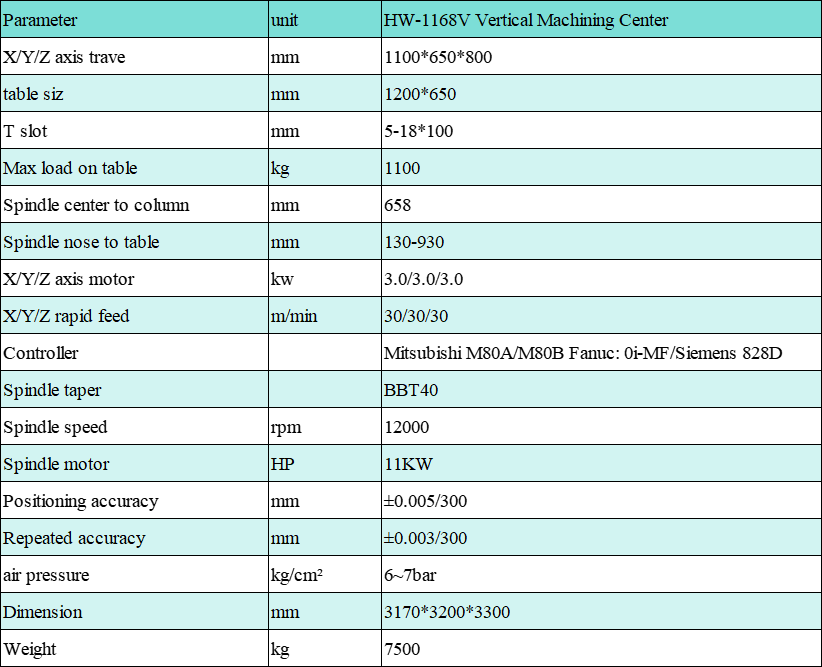

Specification

Feature

▶BBT40 directly connected spindle, compared with the ordinary BT40 spindle, the tool pendulum is smaller at high speed, the tool vibration is smaller, the broach force is stronger, and the tool handle and the spindle are combined with rigidity. Ceramic bearings are used for better precision, rigidity and finish than steel ball bearings.

▶The taper surface and end face of the BBT40 spindle can be tightly fitted to the tool holder at the same time, ensuring the required tool rigidity under heavy cutting conditions.

▶The vibration standard of the direct-connected spindle reaches V1, and the national standard is generally V4. The smaller the vibration of the spindle, the higher the surface processing quality, the continuous machining, the higher the tapping efficiency, and the tool life is extended. The fastest tooth speed can reach 6000 RPM, and the smallest tooth can attack M1.0.

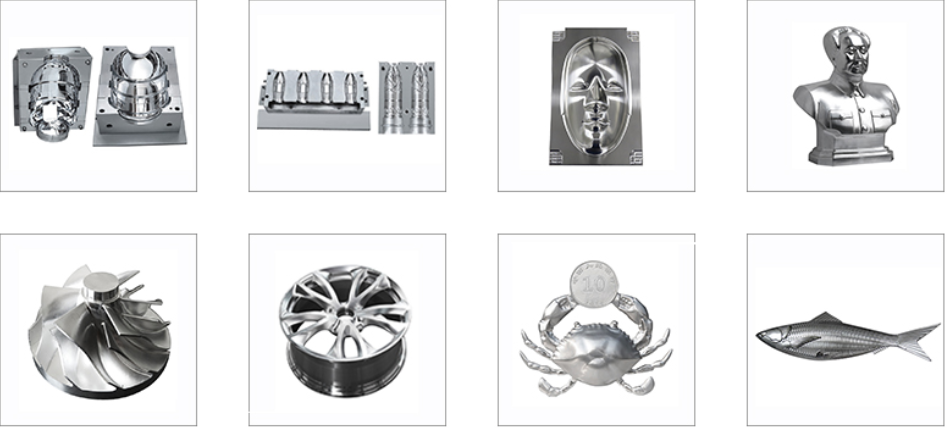

Application