Xenon Lamp Aging Tester

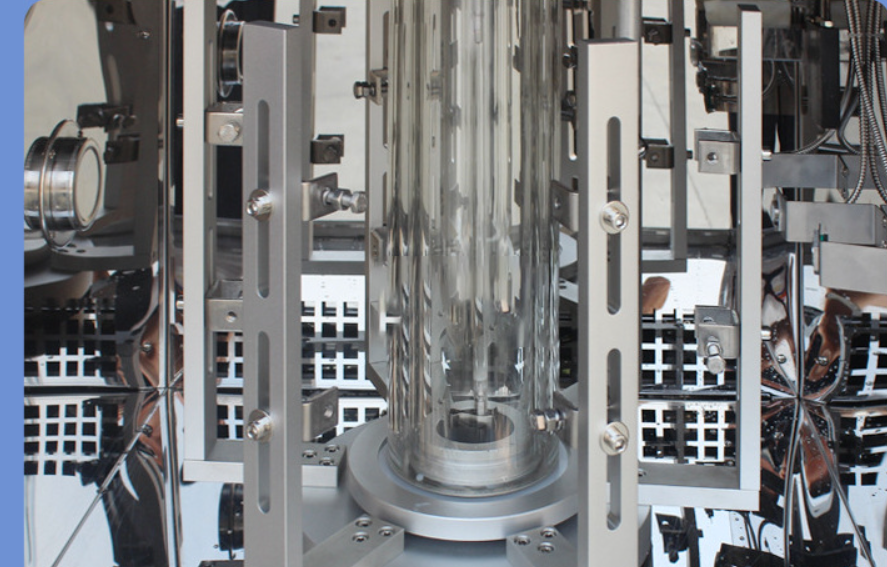

The whole box shell is made of exquisite paint or stainless steel; The inner wall of the laboratory is made of SUS304 advanced anti-corrosion mirror stainless steel plate with reasonable structure design, sophisticated manufacturing technology and beautiful interior appearance.

Technology parameter

| Studio dimensions (mm) | Stu(500x500x600)(W x D x H). |

| Outer box size | (810x1200x1800)(width x depth x height). |

| temperature range | RT+10℃~80℃ |

| blackboard temperature | RT+10-80 degrees Celsius (deviation ±3 degrees Celsius). |

| temperature fluctuation | ≤±2.0C |

| humidity fluctuation | +2%~-3% R.H. |

| Glass window filter | borosilicate glass. |

| Xenon lamp source | air-cooled xenon arc source. |

| xenon lamp power | 3KW |

the total number of lamps | 1. |

| rainfall time | 1~9999 minutes, continuous rainfall is adjustable. |

| rainfall cycle | 1~240 minutes, interval (off) rainfall is adjustable. |

| water nozzle aperture | 0.8mm(return hose hyperfine filter to prevent nozzle blockage). |

| rain water pressure | 0.12~0.15kpa. |

Feature

Smart touch screen

LCD touch screen control is convenient

Watering place

Drawer type, more convenient to add water

Ultraviolet tube

Fluorescent ultraviolet

Simulated sunlight exposure

Beyond the foundational stainless steel construction, modern xenon arc weathering instruments represent the pinnacle of accelerated aging science, integrating spectral engineering, multi-variable environmental control, and predictive analytics. This expansion details the sophisticated subsystems and technological innovations defining high-performance test equipment essential for material durability validation across automotive, aerospace, coatings, and textile industries.

I. Advanced Optical & Radiation Systems

1. Precision Spectral Management

◦ Full-Spectrum Xenon Lamps: 6.5kW water-cooled lamps with borosilicate glass filters replicating:

■ Daylight Spectrum (ISO 11341-A): 300-800nm @ 0.35-1.2W/m²/nm

■ Window-Glass Filtered (ISO 105-B04): 310-400nm cutoff

■ Extended UV Option: 280nm cutoff for military specs

◦ Spectral Fidelity Controls:

Real-time irradiance monitoring via 340/420nm bandpass sensors (±1.5% accuracy)

Automatic lamp power modulation maintaining 0.55W/m²@340nm

Spectral shift compensation algorithms for lamp aging

2. Uniformity Engineering

◦ Rotating specimen carousel (3-5 RPM) with ±8% spatial uniformity

◦ Specimen-to-lamp distance: 300-600mm programmatically adjustable

◦ Reflective anodized aluminum parabolic mirrors (92% reflectivity)

Application

car

coating

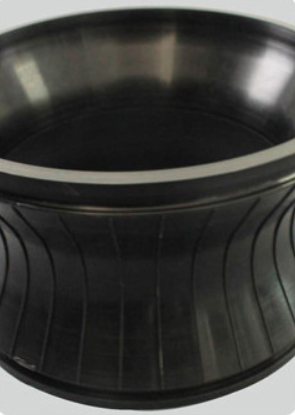

rubber

plastic

cementing agent

fabric