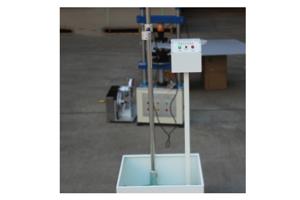

Falling Sphere Impact Tester

Falling ball impact testing machine is used to test plastic, ceramic, acrylic, glass fabric. The robustness of materials and coatings. Conforms to JIS-K6745, A5430 test standards. The machine adjusts the steel ball with a certain weight at a certain height to make the steel ball fall freely hit the test material, according to its damage degree, in order to judge the quality of the test product, the equipment well received by the majority of manufacturers, is a more ideal test equipment.

Technology parameter

Drop height of ball | 0-2000mm adjustable |

Falling ball control mode | DC electromagnetic control |

| Ball weight | 55g, 64g, 110g, 255g, 535g |

| Power supply | 220V, 50HZ, 2A |

Machine size | about 50*50*220cm |

Machine weight | about 15kg |

Feature

Compact and beautiful

Effectively improve work efficiency

Control panel

Visual display

One-click testing

Ultraviolet inversion

Electromagnetic magnet test

Ultraviolet inversion

Instrument ball

5 sets of instrument standard steel balls

While the fundamental principle of dropping a weighted sphere onto materials to assess impact resistance is straightforward, modern falling sphere impact testers embody sophisticated engineering precision, advanced measurement capabilities, and rigorous standardization essential for reliable material characterization. Building upon the core description of testing plastics, ceramics, acrylics, glass, and fabrics according to JIS-K6745 and A5430, this expansion details the critical characteristics defining high-performance systems beyond basic free-fall impact simulation.

1. Precision Mass & Geometry Control:

◦ Certified Sphere Sets: Beyond generic "steel balls," systems include meticulously calibrated sphere sets with traceable certification (NIST, NPL, etc.). Sets cover a wide mass/energy range (e.g., 50g, 100g, 200g, 500g, 1000g, 2000g), often with multiple diameters for the same mass to investigate contact area effects. Materials extend beyond hardened steel (AISI 52100) to include tungsten carbide (WC), chrome steel, brass, or polymer (Delrin) to simulate different impactor hardness and avoid marking softer specimens.

◦ Strict Dimensional Tolerances: Spheres adhere to ISO 3290 Grade 5 or higher tolerances (e.g., diameter variation < 0.25µm, sphericity < 0.08µm). Surface finish (Ra < 0.025µm) is critical to prevent microscopic imperfections influencing impact dynamics.

◦ Mass Verification: Each sphere is individually weighed (resolution ~0.01g) on a calibrated balance, with certified mass documented. Density calculations verify material consistency. Total potential energy (mgh) is precisely calculable.

Application

phone

remote control

bluebooth headset

computer

car charger

recharger