tensile testing machine

It is a mechanical afterforce testing machine for static load, tensile, compression, bending, shearing, tearing, stripping and other mechanical properties of various materials. Widely used in plastic sheet, wire and cable, rubber, textile, steel, glass fiber, pipe, film and other fields

Technology parameter

Model: | Single arm (LCD |

Maximum test force | 5000N |

| test range | 2%-100% of the maximum test force |

| Accuracy level | 1 level |

Test force accuracy | better than ±0.5% of the indicated value |

Deformation display error | Deformation display error :≤±(50+0.15L) |

| test force | Minimum resolution 0.01N |

| Displacement measurement | resolution 0.01mm |

Liquid crystal display content: test force, displacement, peak, running state, running speed, etc | Liquid crystal display content: test force, displacement, peak, running state, running speed, etc |

Feature

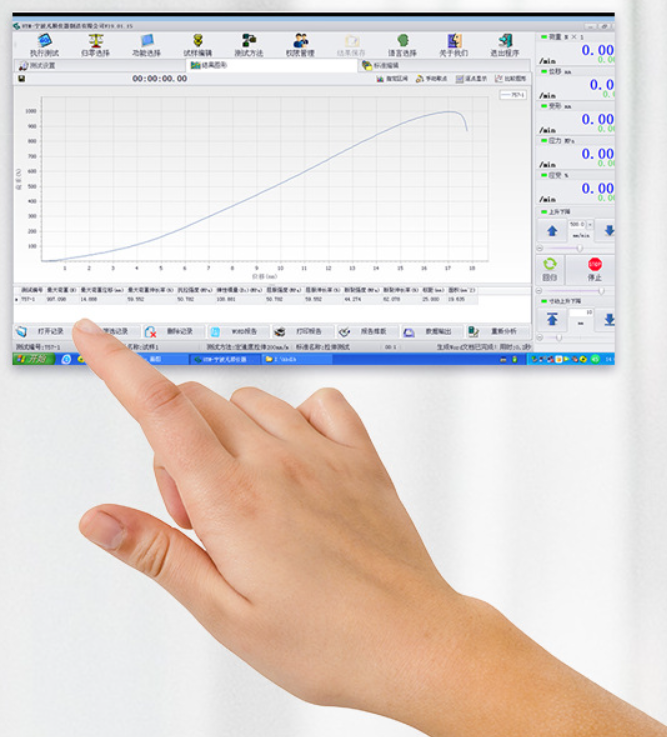

Product operation page

Simple operation, accurate data

Easy to operate

Clear and clear

Factory direct sales

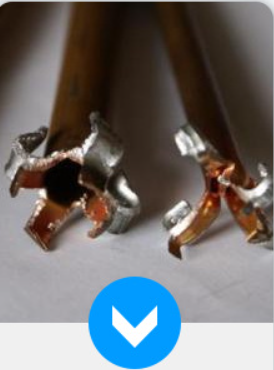

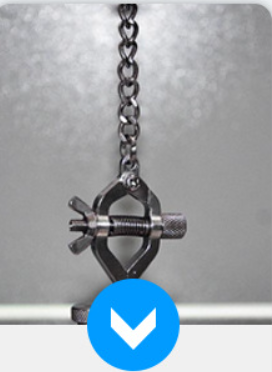

Universal fixture

The fixture is specially designed to hold firmly

Servo motor and governor

Speed control system adopts servo motor and governor, stable and reliable performance, with over current, over voltage, overload protection devices. The speed control range is 1 to 300mm/min.

Precision Force Measurement & Calibration Integrity:

◦ Multi-Cell Capability: High-end machines utilize interchangeable load cells spanning multiple force ranges (e.g., 50N, 5kN, 50kN, 500kN) within a single frame, allowing optimal resolution and accuracy across vastly different material strengths – from thin plastic films to structural steel rebar. Automatic cell recognition and switching are advanced features.

◦ Traceable Calibration: Force measurement is underpinned by rigorous, traceable calibration adhering to international standards (ISO 7500-1, ASTM E4). This involves not just initial factory calibration but scheduled in-house verification using certified dead weights or transfer standards, and periodic accredited laboratory recalibration. Uncertainty budgets are meticulously documented.

◦ Environmental Compensation: Sophisticated load cells incorporate temperature compensation circuits to maintain accuracy despite ambient fluctuations, critical for labs without strict climate control. Some systems actively monitor and compensate for side loads or bending moments that could affect measurement accuracy.

2. High-Fidelity Displacement & Strain Measurement:

◦ Non-Contact Extensometry: Beyond traditional clip-on extensometers, advanced laser and video extensometers provide high-resolution, non-contact strain measurement. This is crucial for delicate materials (films, foams, biological tissues), high-temperature tests, or where contact would influence results. They track multiple gauge lengths and points simultaneously, enabling complex strain field analysis (Poisson's ratio, localized necking).

◦ Integrated Encoder Systems: High-resolution optical or magnetic encoders integrated into the drive system provide precise crosshead displacement measurement. However, the gold standard remains direct specimen strain measurement via extensometers due to system compliance effects.

◦ Strain Rate Control Modes: True materials characterization requires precise control over strain rate (dε/dt), not just crosshead speed. Advanced controllers offer closed-loop strain rate control using feedback from extensometers, essential for generating accurate stress-strain curves and constitutive models, especially for polymers and biomaterials.

3. Advanced Control & Drive Systems:

◦ Servo-Hydraulic vs. Electromechanical: While electromechanical (ball screw) drives dominate for lower forces (<~300-600kN) due to cleanliness, precision, and quiet operation, servo-hydraulic systems are indispensable for ultra-high forces (>1MN), high displacement rates, and demanding dynamic testing (though static load is primary here). Each system requires sophisticated servo-valve or servo-motor control.

◦ Multi-Stage Control: Tests often require complex profiles: initial pre-load at low speed, ramp to constant strain rate for elastic/plastic region, hold at peak load, controlled unloading, cyclic loading. Advanced controllers seamlessly transition between position, strain, force, and stress control modes within a single test sequence.

◦ Stiffness & Resonance Management: Frame design is paramount. High stiffness minimizes energy storage and ensures force application is directly to the specimen, not deforming the machine itself. Finite Element Analysis (FEA) optimizes frame geometry to push structural resonance frequencies far above typical test frequencies, ensuring dynamic stability.

Application

stretch

compress

bend

shear

tear

peel off