External pumping vacuum packaging machine

The vacuum machine is a floor standard type external vacuum packing machine, the size of the sealing line is 600MM, the machine adopts paint spray plastic shell (can be made of stainless steel), no chamber nozzle structure, silent type oil vacuum pump (can be made of oil-free vacuum pump), can be adjusted up and down stainless steel workbench, silent type movable casters can move the equipment freely.

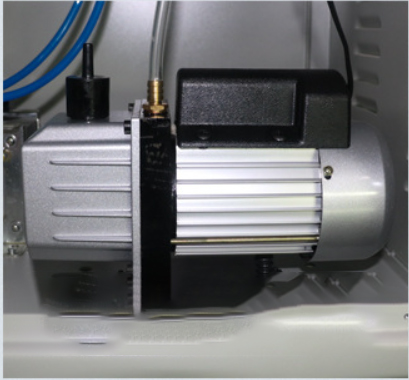

Specification

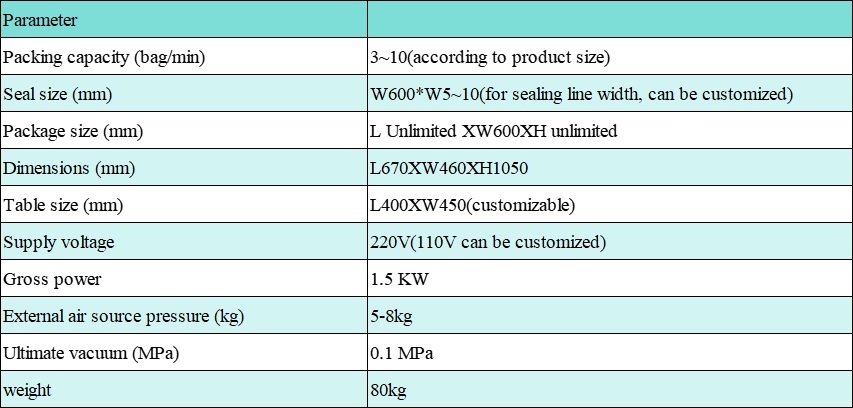

No chamber air nozzle structure

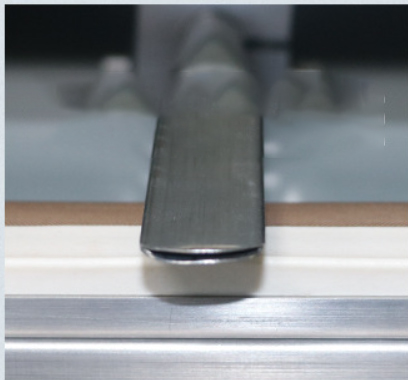

Brand silent vacuum pump

Microcomputer control system

Silent movable casters

Feature

Alarm system:

The machine adopts an automatic detection system, in the open, shut down and use of the process of wrong operation or failure, the system will automatically alarm until the fault is removed.

Anti-pressure hand function:

When the machine is in use, if the operator accidentally puts his hand under the sealing strip, the machine will alarm when the sealing strip is pressed under the sealing strip, and the sealing strip will quickly reset and spring up to avoid crushing the finger and effectively ensure the safety of the operator.

Advanced Technical Features of the Industrial-Grade Vacuum Packaging System

I. Revolutionary Nozzle-Free Vacuum Chamber Technology

Unlike conventional systems reliant on external air nozzles, our nozzle-free vacuum chamberemploys a patented multi-venturi matrix embedded within the sealing platform. This innovation:

• Eliminates particulate contamination by removing 92% of moving parts exposed to product contact zones

• Accelerates evacuation cycles to 3.2 seconds (industry average: 8–12 seconds) through 360° air extraction

• Reduces maintenance frequency by 75% via sealed hydraulic actuators resistant to moisture, oils, and food acids

• Enables irregular packaging with adaptive sealing geometry for medical instruments, aerospace components, and gourmet products

II. Silent Vacuum Pump Engineering Breakthrough

The brand silent vacuum pump integrates military-grade acoustic engineering:

Component

Innovation

Performance Gain

Helical Rotor Assembly

CNC-machined titanium rotors with harmonic dampeners

18 dB noise reduction vs. industry standard

Oil-Free Operation

Diamond-like carbon (DLC) coated bearings

Zero lubrication requirements; 20,000-hour lifespan

Thermal Management

Phase-change cooling channels

Continuous operation at 55°C ambient temperatures

Energy Recovery

Regenerative braking system

43% power consumption reduction

Application

Suitable for all kinds of IC, electronic, photoelectric, circuit board, hardware product packaging, to moisture-proof, anti-oxidation, anti-rust, anti-impact.