HW-850L Linear Guide Vertical Machining Center

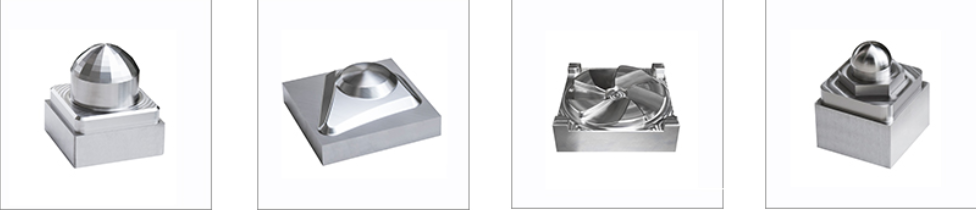

It is mainly used for the automatic mass processing of parts and molds,

such as complex cams, sample board, dies and arcs, and is widely applied

in electronics, machinery, automotive, motorcycle, automation, medical equipment and other industries.

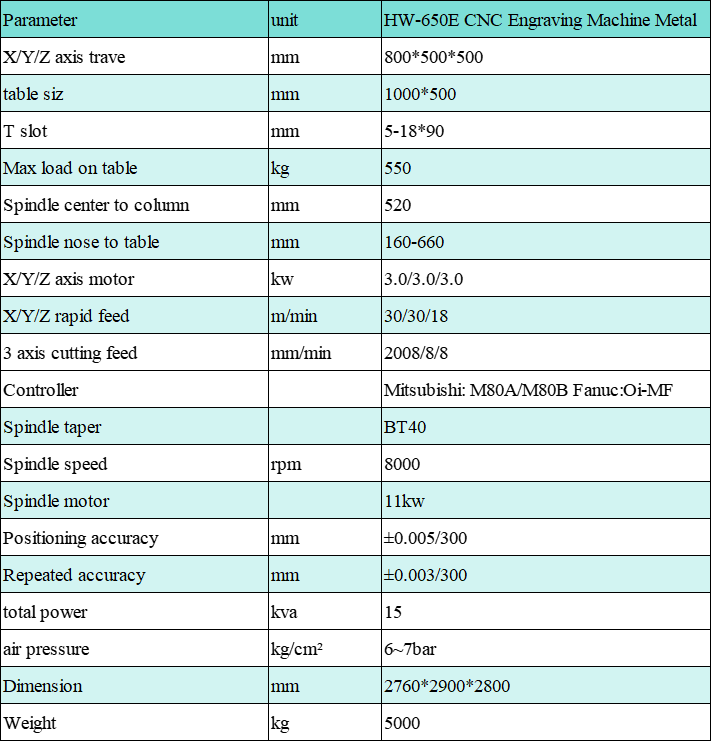

Specification

Feature

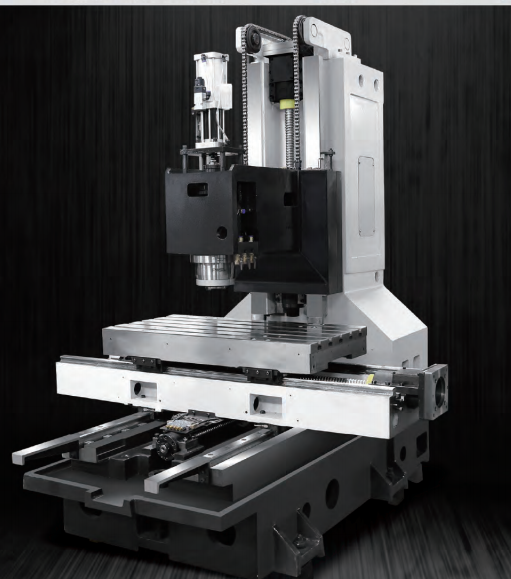

▶X.Y axis rail, Z-axis hard rail to ensure good circular accuracy and cutting force.

▶Box base, long span A-column, to ensure good accuracy retention.

▶Precision ball screw adopts double nut design, and five ball bearings are used at

both ends of the support seatIt is locked and pre-drawn to offset the thermal elongation

error of the screw and ensure the thermal stability of the machine tool.

▶All lubrication systems are equipped with positive displacement distribution valves to ensure uniform oil supply at all lubrication points. Hold the machine good lubrication, prolong the service.

The tool store adopts the technology of releasing the tool in advance. The tool change time is 2.3 seconds (knife to knife).

24 knife count

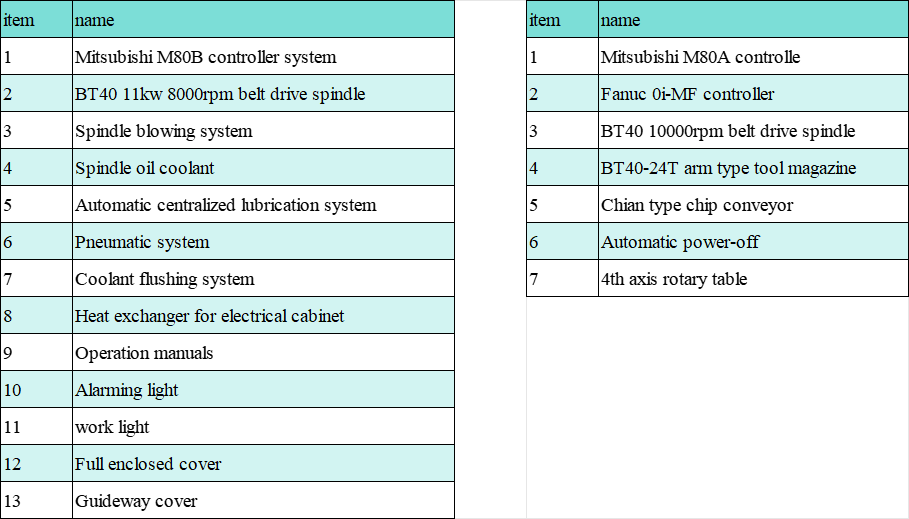

Configuration

Application