HW-V11 Vertical Parts Machining Center

It can continuously complete drilling, milling, tapping, boring, reaming and other machining processes by once clamping, and can

complete coordinate boring and fine machining of complicated parts and molds accurately and efficiently.

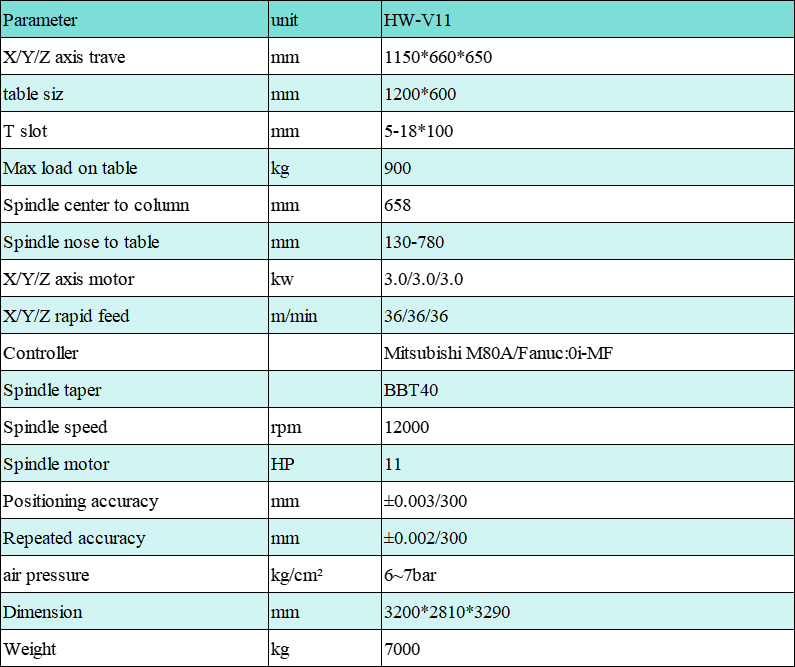

Specification

●High rigidity moving parts with lightweight design for high speed and high precision parts processing, faster and more powerful parts processing machine.

●High strength gray casting iron machine body remains a high rigidity and stability even a long time processing.

●Special large span structure column and double-layerd base could bear higher inertia gravity and improve dynamic responsiveness of the whole machine.

●V1 vibration standard of direct drive spindle, compared with most popular V4vibration standard, has smaller spindle vibration and better surface processing performance.

●Heavy loading ball linear guide in 3 axis, max rapid feed speed 48 m/min. The fastest tapping speed can reach 6000 rpm, the smallest tooth can attack M1.2.

Feature

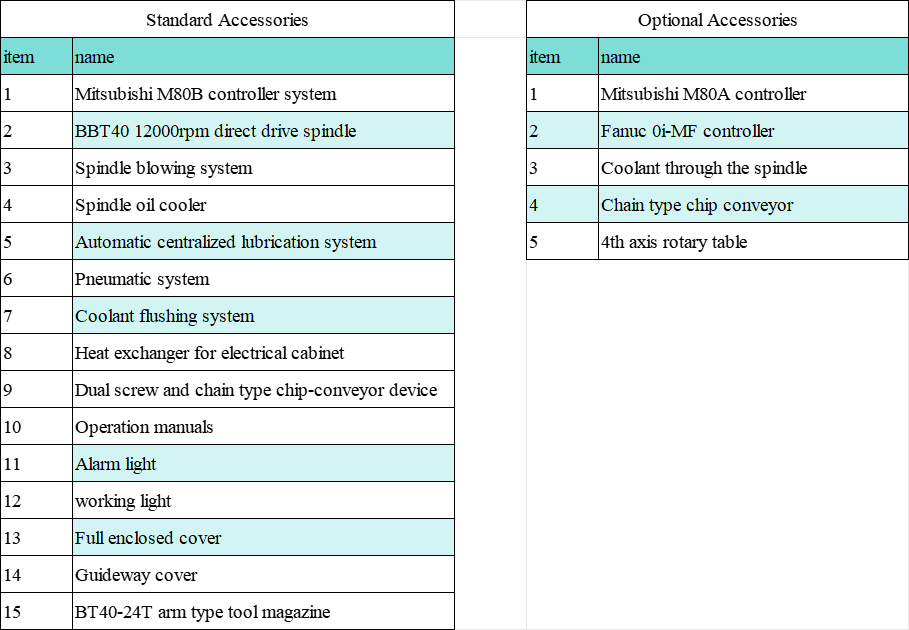

Optional configuration

Spindle center discharge

Chassis Y direction twin-screw chip removal machine

4axis rotary table

5 axis rotary table

Tool setting apparatus

Configuration

Application

This series of machine is widely used for mass production of small And medium-sized cabinets, covers, panels, shells and plates in high-precision molds, automobiles, machinery, instrumentation, light industrial textiles, electronic instruments, precision metal products, precision mold products and machinery manufacturing industries.