HW-1370V Vertical Machining Center

The series of models adopts high-rigidity structure supported by long span, X/Y/Z axis high-precision linear guide rail and ball screw design with locking preload design, which can provide you with fast, strong and stable machining performance, making it suitable for high-precision parts processing and mold processing.

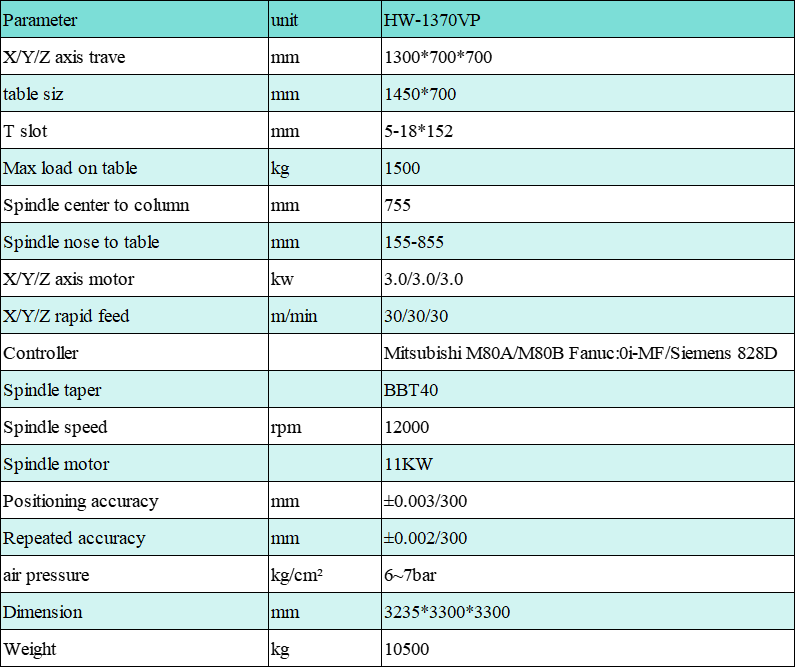

Specification

Feature

Increase and widen the large span herringbone design

Internal encryption and thick bone arrangement, compared with the ordinary column, the body rigidity,

torsion and bending resistance is enhanced. At the same time, the contact surface with the base is increased,

and the processing is more stable.

Y-axis four-wire rail

The X-axis support is more stable and improves processing stability

The X axis and Z axis are linear guides with three sliding blocks and rollers

Ensure the large load bearing capacity of the workbench and the cutting rigidity of the 2 axes

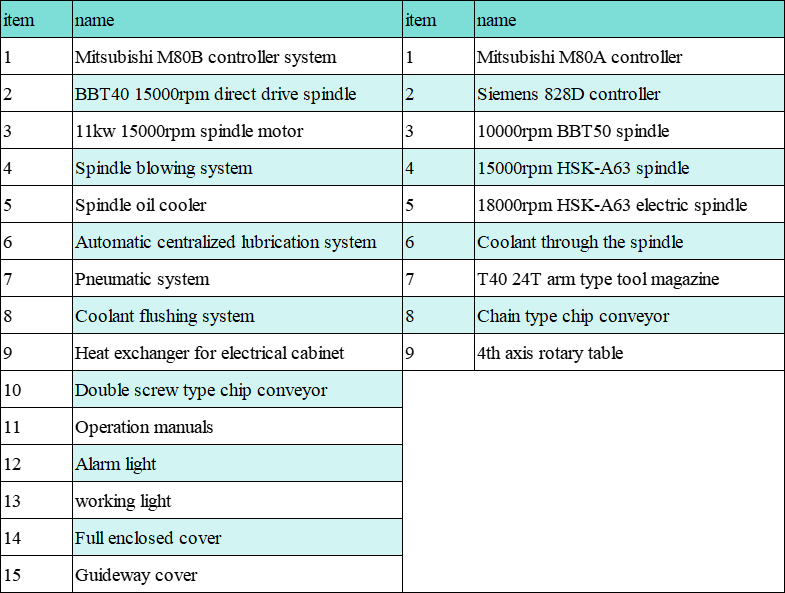

Configuration

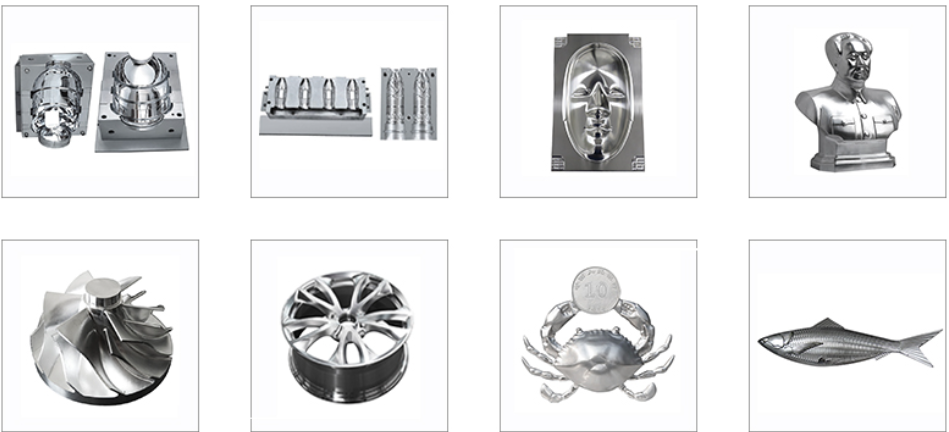

Application

It can continuously complete drilling, milling, tapping, boring, reaming and other machining processes by once clamping, and can complete coordinate boring and fine machining of complicated parts and molds accurately and efficiently. This series of vertical machining center is widely used for mass production of small and medium-sized cabinets, covers, panels, shells and plates in high-

precision molds, automobiles, machinery, instrumentation, light industrial textiles, electronic instruments, precision metal products, precision mold products and machinery manufacturing industries.