HW-1160V 4 axis vertical machining center

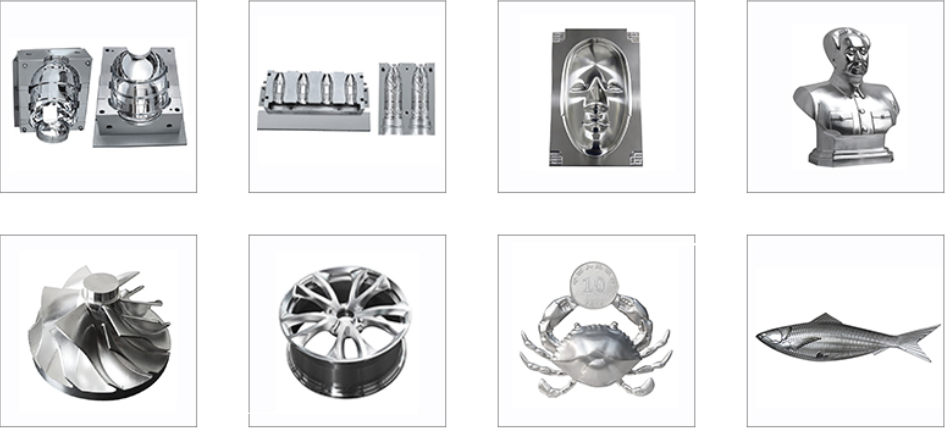

HW-1160V four-axis vertical machining center is widely used in the processing of various mechanical parts, molds, fixtures, auto parts and other fields. Due to the characteristics of high precision and high efficiency, it is especially suitable for the processing of complex parts, such as the processing of complex cavities, hole systems, curves and other parts. It is widely used in aviation, aerospace, automobile, mold manufacturing, precision machinery and other fields.

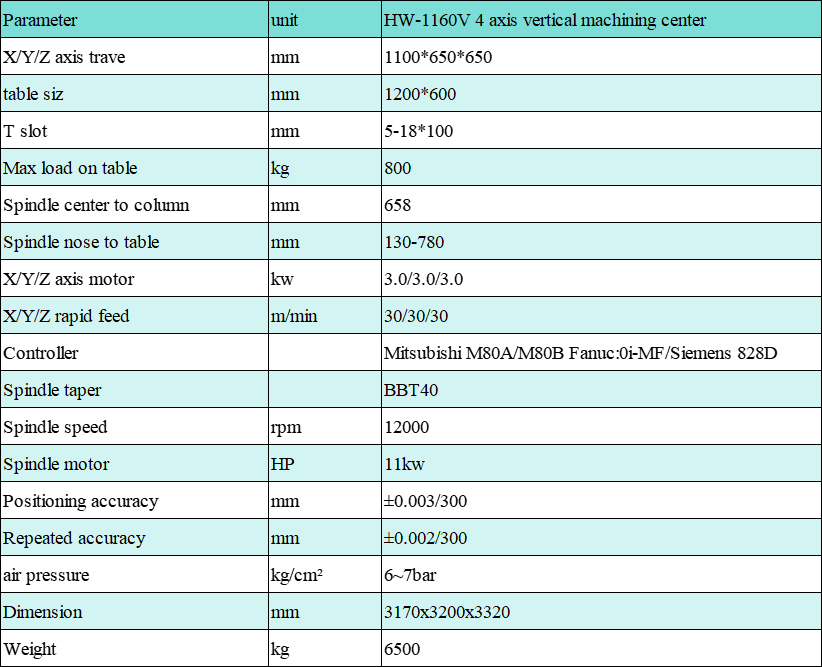

Specification

Feature

1. High precision: The use of advanced CNC system, combined with precision transmission mechanism, can achieve high processing accuracy, to meet the processing needs of various precision parts.

2. High efficiency: equipped with high speed spindle motor and fast moving axial motion, greatly improve the processing efficiency and shorten the production cycle.

3. Good stability: stable structure, stable operation, can ensure the stability of long-term continuous work.

4. Easy operation: humanized operation interface and control system, so that the operator can easily program and operate.

5. Easy maintenance: Modular design, easy and fast maintenance, reducing maintenance costs.

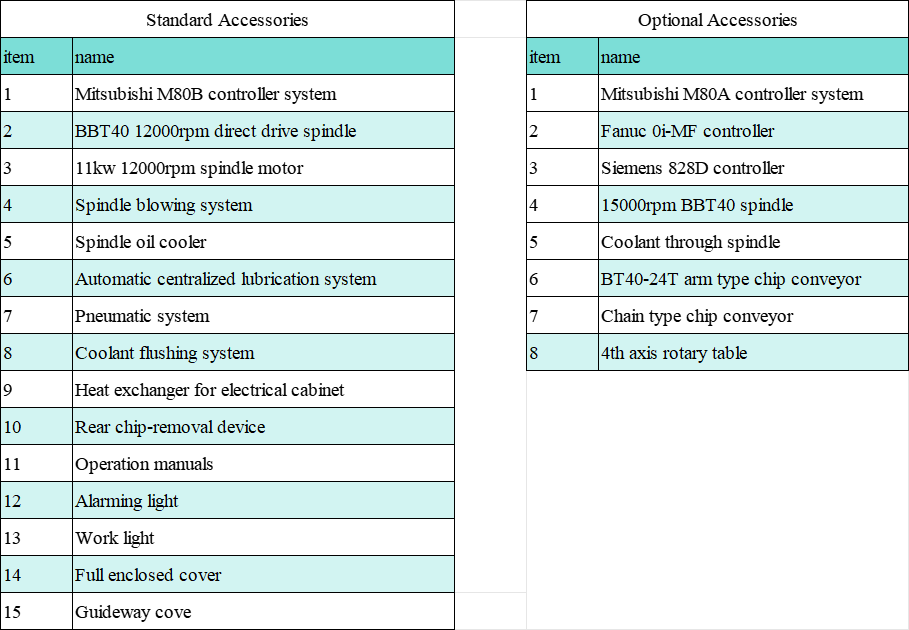

Configuration

Feature

In the application of mechanical parts, molds, fixtures, auto parts and other fields, the advantages of four-axis vertical machining centers are particularly prominent. It can realize the efficient and high-precision machining of complex three-dimensional contours and surfaces, and is suitable for the processing of parts with complex shapes and high precision requirements, so as to meet the needs of various production fields. Therefore, the four-axis vertical machining center has become one of the indispensable CNC equipment in modern manufacturing enterprises.