HW-1370VP Vmc Vertical Machining Center

Full support box base structure,X axis on the bottom, Y axis on the top; Ensure that the table is always in full support condition within the full travel range of the XY axis, and avoid the shortcomings of the conventional vertical machining center table when it moves to the positive and negative limit position of the X axis.

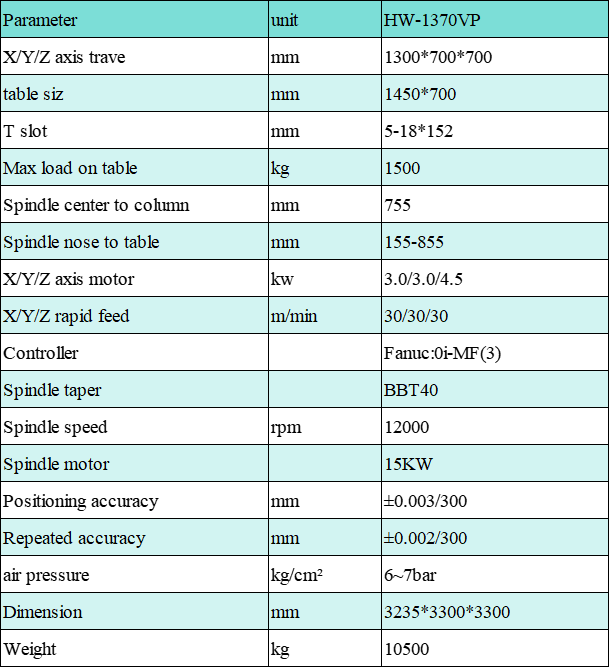

Specification

Feature

Bidirectional fully supported bed structure

Three-axis ball screw Thermal expansion suppression system (optional)

Large diameter bead roll screw hollow design, constant temperature cooling oil is sent from the inner tube to the end of the bead screw and returned and the heat generated by the screw movement is discharged, long-term processing will not cause the workpiece center drift due to the advantages

The X axis and Z axis are linear guides with three sliding blocks and rollers

Ensure worktable load bearing and Z-axis cutting rigidity

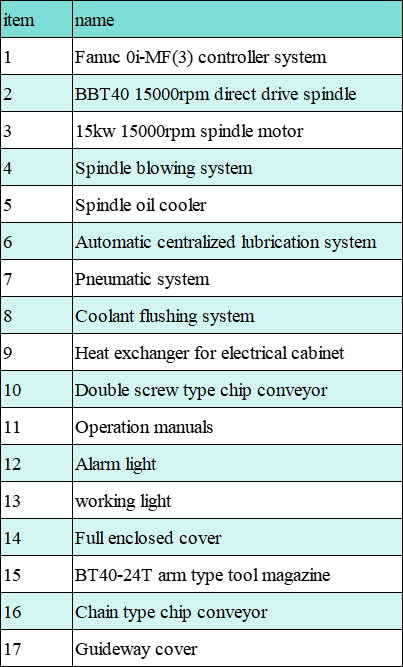

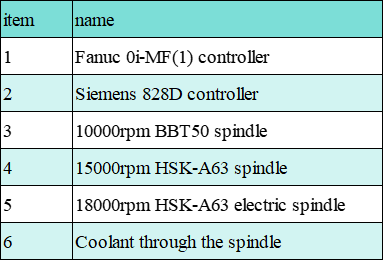

Configuration

Application

It can continuously complete drilling, milling, tapping, boring, reaming and other machining processes by once clamping, and can complete coordinate boring and fine machining of complicated parts and molds accurately and efficiently. This series of vmc vertical machining center is widely used production of small and medium-sized cabinets, covers, panels, shells and plates in high-precision molds, automobiles, machinery, instrumentation, light industrial textiles, electronic instruments, precision metal products, precision mold products and machinery manufacturing industries.