HW-850V Vertical Machine Center

The hw-850V's ultra-rigid structure and X/Y/Z axis high-precision linear guide and ball screw design with locking preload provide you with fast, robust and stable machining performance, making it suitable for high-precision parts processing and die processing. It can be widely used in automotive, machinery, instrumentation, light industrial textiles, electronic instrument industry, and can fully demonstrate high-precision and high-efficiency processing capabilities at a very reasonable cost.

Parameter

processing range | X-axis travel | mm | 800 |

| X-axis travel | mm | 500 | |

| X-axis travel | mm | 500 | |

| Distance from spindle nose to table | mm | 140-640 | |

| Distance from spindle center to column rail surface | mm | 520 | |

workbench | table size | mm | 900*500 |

| maximum bearing capacity | kg | 600 | |

| T shaped groove | No. | 5-18*100 | |

| Numerical control system | Fanuc System | oi-MF | |

Principal axis | Connection mode | Straight-knot form | |

| Spindle speed | rpm | 12000 | |

| Spindle taper and specification | BBT 40 | ||

| Spindle motor power | kw | 15-12000rpm | |

| Spindle torque | Nm | 52.5/70/95.5 (S1/S2 60min/S2 15min) | |

triaxial | X, Y, Z three-axis motor power | kw | 3.0/3.0/3.0 |

| X, Y, Z three-axis motor torque | Nm | 20/45 | |

| X, Y, Z fast moving speed | m/min | 30/30/30 | |

| Machine tool accuracy | Positioning accuracy (X/Y/Z) | mm | 0.003/300 |

| Repeated positioning accuracy (X/Y/Z) | mm | 0.002/300 | |

| other | Machine outline dimension | mm | 2600X2750X2900 |

| Main engine weight | kg | 5500 |

Feature

Machine head

Strengthened cross-ribs to increase bending and

torsion resistance.

Column

Box structure large span A type column with high

rigidity to ensure stability during machining.

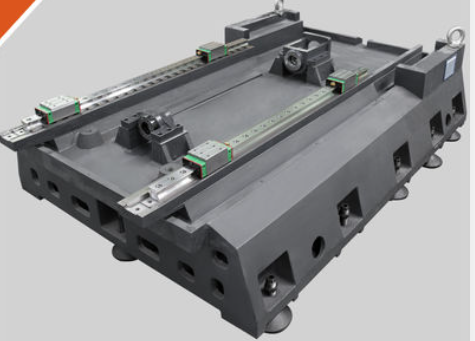

Base

Double layered box type base to ensure high stability

and rigidity.

Saddle

Double T extra-wide structure to improve rigidity and

stability during rapid feed

Spindle head

Box structure spindle head to increase cutting rigidity,

improve the machining efficiency.

Guide way

3 axis ball/roller linear guideway, rapid feed is

48m/min.

Slider

Z axis 3 sliders to increase the stability and accuracy

during machining.

Screw

C3 grade high precision ball screw with pre-extension

process, improve the transmission rigidity and

machine accuracy

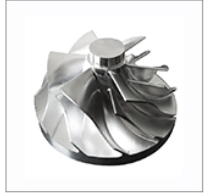

Spindle

Belt/direct drive spindle with spindle oil coolant and

blowing system to ensure spindle precision and

stability under high speed running.

Controller system

Mitsubishi/Fanuc/Siemens controller system optional.

Configuration

Main parts list of machine tools

| 1 | Control system | FANUC | 11 | Electrical box heat exchanger | Riko |

| 2 | Spindle motor | FANUC | 12 | Cutting cooled motor | Lorex |

| 3 | Three axis motor | FANUC | 13 | Three-point combination | Gold |

| 4 | Three axis screw | NSK | 14 | Air source handling element | Gold |

| 5 | Three axis rail | Rexroth /THK | 15 | Main contactor | Mitsubishi |

| 6 | Bearing | NSK | 16 | Molded case circuit breaker | Mitsubishi |

| 7 | Coupling | R+W/NBK | 17 | Relay | Omron |

| 8 | Knife punching system | Shinaka | 18 | Switching power supply | Omron |

| 9 | Air path system combined with solenoid valve | Gold | 19 | Wire (oil resistant wire) | Sai Yang |

| 10 | Main shaft cooling system | Riko | 20 | Hand wheel race | Sai Yang |

Application

It is broadly used in the industry of automobiles, machinery, instrumentation, light industrial textiles,

electronic instruments, can fully present high precision and high-efficiency machining ability at a very reasonable cost