HW-650V Vertical Machining Center

High precision and high efficiency series.

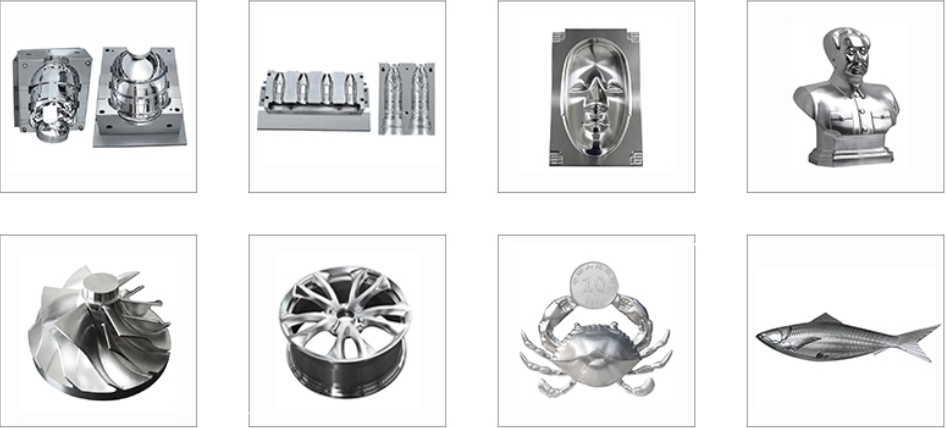

High speed high precision VMC for molds processing. We utilizes its mature vertical machining centers

techniques to present you with the HW-650V, which is special design for the industries in 3C component

machining and small die-&-mold machining.

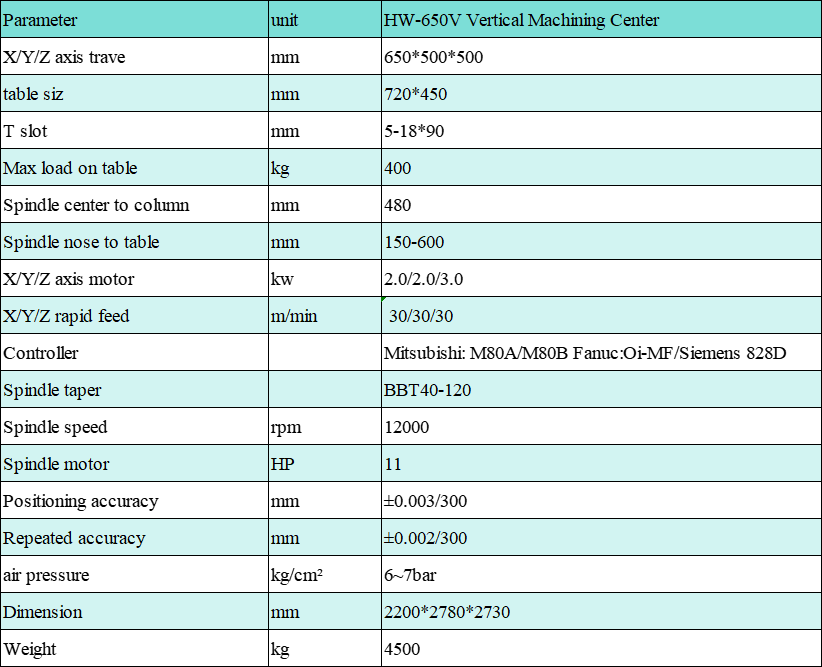

Specification

●High grade gray casting machine body design through The Finite Element Method(FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

●All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

●All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

●Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

●V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

Feature

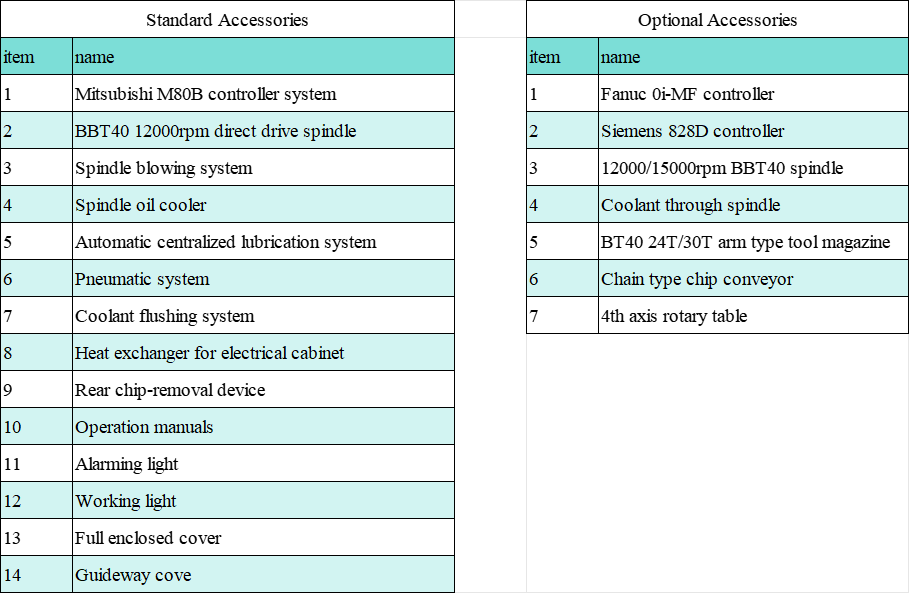

Configuration

1. Optimize the process flow: through reasonable process planning, reduce unnecessary processing steps and waste, make the whole process more compact and efficient.

2. Choose the right tool and fixture: Choose the tool and fixture suitable for the mold material and processing requirements to improve the processing efficiency and accuracy.

3. Optimize the numerical control program: By optimizing the numerical control program, the moving path of the tool is more reasonable, reducing the idle time and improving the actual working time.

Application